If you are going to do manicure professionally, you cannot do without special equipment. Each nail service technician must have a staffed workplace, regardless of where the work takes place - in the salon or at home. Therefore, the choice of a manicure table when working with nails is very, very important. And today we will look at what these tables are like and what you should pay attention to when purchasing. For those choosing a manicure table, photos with dimensions can give a number of interesting ideas.

Why is a comfortable table so important?

When working, a manicurist has to concentrate for a long time and perform small, neat actions. All this requires convenience and carefully selected working attributes, which include a table. In addition, it is important to optimally place all the necessary cosmetics and manicure tools on its working surface.

The parameters of a professional’s workplace are strictly regulated. The height of the manicure table cannot be less than 700 mm; the tabletop material must be waterproof due to the need for constant disinfection of its working surface. If work is carried out for several people in one room at once, the tables should be no closer than three meters from each other.

The manicure room must have a source of water for cleaning working tools. The interior of the room and attractive design are what any manicure business owner pays close attention to. And he does the right thing - the aesthetic impression that the salon leaves on the client is an important success factor, a guarantee that the woman will return to this place more than once.

Accessories for manicure table

There are a number of devices that will greatly facilitate the work of working with nails. Let's look at the main ones.

Hood or vacuum cleaner

When correcting nails and other procedures, dust is generated that must be removed. For this purpose, the tables are equipped with a small hood. Basic requirements for the accessory:

- Quite powerful but quiet engine.

- Compact housing located under the table. It should not create inconvenience by touching the feet of the client or the master.

- The dust bag must be in a plastic case. This eliminates the possibility of dust getting on clothes.

- The holes through which air is exhausted are directed to the sides. This will prevent airflow from the legs.

- The upper grille has small gaps. This prevents the client's nail or finger from accidentally getting on the fan blades.

One of the popular manufacturers that meets all the listed requirements Descartes .

There are models that do not require embedding. The suction part is also a hand rest. The collection bag and the motor are located in a housing that is installed side by side. But the presence of a connecting hose somewhat reduces the useful working area.

Lighting

Another important point. Beginning craftsmen settle on an ordinary table lamp, which is fundamentally

wrong.

Basic requirements for the device:

- Sufficient light bulb power (minimum 60 watts in terms of an incandescent lamp).

- Body flexibility . Either a special metal tube or a system of moving components is used.

- Possibility of attachment to the base of the table top. This prevents the device from falling and makes it easier to adjust to each specific hand.

It’s easy to choose such a product; the price will be up to 1,500 rubles.

Little things

There are a few more secrets from experienced craftsmen that will allow you to use the table for a long time:

- Disposable covers. Ensures durability of surfaces.

- Spare accessories. Light bulbs, mechanical table parts and more. A stock of such little things will make it possible not to be distracted by searching for suitable consumable components in the event of their failure.

- Additional movable cabinet. As practice shows, a good craftsman always does not have enough space to store tools, no matter what design the table is.

The main thing in the work of a manicurist is convenience for himself and the client. At the same time, a vacuum cleaner and additional light will protect you from health problems, allowing you to work long and fruitfully.

Other subtleties of interior arrangement

That is why the number of jobs for manicurists rarely exceeds 4. With a larger number, clients lose the feeling of comfort. It is advisable that each table should be located by the window, since in daylight it is easier for the master and the client to coordinate and perceive color shades.

The manicure room must be equipped with ventilation to remove unpleasant and toxic odors. Of course, there is nothing to say about the level of cleanliness that must be maintained, and the need for salon hostesses to always be smiling and friendly.

It would also be a good idea to make a reservation in advance and organize armchairs or a sofa and a table with a supply of fashion magazines. Or better yet, a TV or music system.

Basic purchase requirements

When buying a manicure table for a salon, you should pay close attention to the material of manufacture, the shape of the item itself and its functionality. It is especially important what the countertop is made of. The requirements for it are quite high. The surface must be moisture-resistant and resistant to chemicals. From a decorative point of view, there is no fundamental difference between matte and glossy countertops, but it should be comfortable to the touch, since manicure is a lengthy procedure.

The shapes of tables offered by salon industry enterprises are varied in design and configuration. They can be square or round, equipped with cabinets - both built-in and retractable, and it is sometimes difficult for the master to make a good choice.

The equipment included in different models can also vary significantly. To make a quality purchase, the master must clearly understand the functionality of the future purchase, and how the table will be placed in the salon. The size of the manicure table should be selected according to the available free space. It is not necessary to purchase a copy that is too large - it will clutter the room and will not necessarily be convenient for work. Buying an overly miniature table is also questionable. If space allows, it is better to buy a full-fledged table with normal dimensions.

Step-by-step manufacturing instructions

It will be easiest to assemble the table if all the parts have already been cut - the parts just need to be connected to each other. If the project is carried out independently from start to finish, you will have to work hard: first cut out all the parts and fasteners, and only then assemble them into a single structure.

It is better to make the body of the manicure table from chipboard, the tabletop and facades from laminated chipboard.

How to make a manicure table with your own hands:

- The chipboard sheet must be laid out on a flat surface and cut into components. We must try to carry out this procedure with a minimum of waste.

- All ends are covered with veneers. Having connected the main part and the decorative strip together with glue, you need to walk over the surface with a hot iron. This way you can achieve better adhesion of materials.

- In the places marked according to the drawing, you need to drill holes where the fasteners will go.

- After the preparatory work has been completed, all elements must be connected to each other. If the table is not planned to be disassembled in the near future, you can pour glue into the grooves of the fastenings - this will make the structure stronger, and situations with shelves falling out (often encountered among beginners) will automatically be eliminated.

Manicure tables made independently are almost in no way inferior to similar products produced in furniture factories.

If you plan to install a built-in hood, even at the cutting stage it is necessary to drill a corresponding recess for it. There is no need to glue it with veneers - the cut of wood will be covered by the device itself. It is possible to make a hood for a manicure table with your own hands, but its cost is not much less than that of a ready-made one. That is why it is easier to purchase a built-in model ready-made.

Additional equipment, in particular an exhaust vacuum cleaner, plays a significant role in the work process.

Important! For attachment points, you need to make an indent from the edge of the walls - at least 20 mm.

The equipment can be purchased ready-made or made independently using an electric motor with blades, as well as a power supply.

What are they like?

A future purchase can be classified into one of three classes. The lowest of them (economy class) is represented by a model range with minimal functions. Such tables are useful either for home use or for very tiny manicure salons. The necessary additional accessories for such a table are often purchased separately.

A classic manicure table usually combines a low price and a modest, elegant design. The material from which such a table is made is relatively inexpensive. The dimensions of a standard type manicure table, as well as the offered set of functions, usually satisfy the professional needs of the owner and that is why the classic version enjoys enduring popularity.

If you decide to purchase a premium table, you will receive, in addition to high quality, many functions and a number of additional accessories. In addition, such tables often represent a very interesting design solution. They may come complete with a hood, an original lamp or stand, etc. Such tables are mainly equipped in elite beauty salons. The size of a manicure table with drawers in this case can be quite significant.

Other classification

In addition to dividing into classes, the tables are very different from each other in design, functionality and folding mechanism. Your purchase may be stationary or mobile, or it may look like a set for several places to work at once.

Stationary tables are usually found in all nail salons where space allows. Most often, they are equipped with a variety of accessories and fixtures - from shelves and special lighting to hoods, etc. Some models are equipped with built-in lamps.

A manicure folding table, the size of which will suit someone who works at home or in a small cramped room, can be a solution if there is a lack of space. When assembled, it takes up very little space. The design and configuration of such tables can be very different, and the folding mechanism can be manual or automatic.

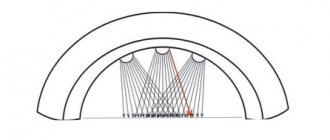

There are also stands where a master can do an express manicure. They are placed in nail bars, where busy people come and receive a quick manicure from nail technicians. The equipment set consists of a bar counter designed for several people to work at once, seating in the form of armchairs for staff and clients, as well as additional shelving and cabinets for tools. By purchasing such a kit, you can organize an express manicure point in any free corner of a shopping center or beauty salon.

Main types of manicure tables

Before choosing a manicure table, you should research the types of equipment. Thus, all manicure tables may differ in appearance, mechanism design, and ease of use. There are stationary, folding tables, complexes of several workplaces.

Stationary

All salons that have enough space in the hall give preference to stationary tables for manicure. Most often, they are supplemented with all kinds of auxiliary equipment: lighting fixtures, hoods, shelves for tools, etc. Some have movable wheels for ease of movement.

Folding

In cramped conditions of a small space, you can choose a folding manicure table. It is convenient because when folded it takes up very little space. Folding tables vary in external design, configuration and folding mechanism (can be manual or automatic).

Stand for express manicure

This type of equipment is found in nail bars. Here customers can receive fast service. The stand set includes a table, chairs for staff and clients, and special cabinets for manicure accessories. Several craftsmen can work behind it at the same time. Typically, such equipment is used in beauty salons or shopping centers.

Based on your needs, you can choose a stationary or folding manicure table. Each type of equipment comes complete with additional elements and accessories. Read on to learn what else you need to consider when choosing a high-quality desk.

Read the material on the topic: Files with a logo are a great option for promoting your business

What you can't do without

As an accessory for a manicure table, we should mention a source of directional light, which can be desktop or built-in. This attribute is required; no professional can work without it. Good lighting is the key to accurate and accurate work. Modern coatings (gel and shellac) require special LED or ultraviolet lighting lamps.

In addition to the hood, to eliminate unpleasant and toxic fumes, you need a manicure vacuum cleaner, with which the work surface is cleaned of dust and dead skin and nails.

Of course, you can’t do without comfortable chairs designed for both the master and the client, and a retractable cabinet on wheels where numerous equipment will be stored. To protect the tabletop, you can buy disposable covers; it also makes sense to take care of replaceable fittings, especially relevant for folding manicure tables, as well as lubricant for their mechanism.

What to look for when choosing?

It will be easier to purchase a high-quality and comfortable table if you know the basic requirements of professionals for such equipment:

- Table legs must be equipped with rubber tips. This gives the structure stability. The wheels cannot be used even with a locking mechanism. Sooner or later the table will start to move randomly, which will significantly complicate the work.

- The presence of a bedside table on wheels. Even more mobility and convenience.

- A large number of niches , drawers and shelves. This will allow you to have everything you need at hand without creating a clutter on the work surface.

- Table size . There is no point in chasing large sizes. This will only reduce functionality. Experts consider the following ratio to be optimal: length 1.2 meters;

- height 75 centimeters;

- width 45 centimeters.

- chemical aggressive media (varnishes, solvents, etc.);

Manicure table size according to GOST

When purchasing, a lot depends on the height of the artist, because when treating the client’s nails, he remains in a stationary position for a long time and should not experience discomfort. Here the size of the manicure table plays a decisive role.

As a rule, manufacturers focus on a certain average option. The standard sizes of a manicure table, suitable for most professionals, are models with a height of 73 to 75 cm and a working surface with a length of 100-120 cm and a width of 45 to 50 cm. In terms of shape, it is best to purchase a table with a smoothly curved line of the table top.

If acrylic is supposed to be used for manicure, a hood must be present at the workplace. Dangerous chemicals can cause not only discomfort, but also serious consequences such as dizziness, nausea or allergies.

If the size of the manicure table does not allow it to be equipped with a built-in hood, then one should be installed separately in the room. The hood can combine the functions of a vacuum cleaner for the work surface.

Assembling a standard table design

To make a manicure table from laminated chipboard yourself, you should prepare tools in advance and purchase materials. To work you need:

- Laminated chipboard, 16 mm.

- PVC edge 2 mm and 0.4 mm.

- Stable metal leg.

- Handle for the bedside table.

- Self-tapping screws, rods, confirmations, eccentrics.

- Shelf holders, dowels 10 mm.

- Furniture hinges.

- Construction adhesive.

During the work process, a standard set of tools is used. Additionally, you will need a tape measure, a pair of Phillips screwdrivers, a pencil, a ruler, scissors, and hexagons. All actions are carried out in stages. The description of the work and the dimensions of the structural elements deserve special attention.

Drawing and preparation of materials

To make a high-quality manicure table, you must first make a drawing. It will help you avoid mistakes in your work. You can create a diagram yourself or use special computer programs for furniture makers: PRO100, Astra, Basis, Volumetric.

You need to start work by determining the parameters of the manicure table. The standard length of the working surface is 115 cm, width from 45 to 50 cm. As for height, 75 cm will be enough.

Next, parts are cut with the dimensions indicated in the drawing. To assemble a simple comfortable table you will need the following parts:

- Table top 95x48 cm.

- Bottom bar 46x30 cm.

- Sidewalls 75x46 cm.

- Door 40x30 cm.

- The back wall of the cabinet is 75x30 cm.

- Large shelf 45x29 cm.

- Small shelf 45x28 cm.

Drawing of a dressing table for making it yourself, stages of work

Using the drawings, holes are prepared in the cut elements. The edges of each part are covered with PVC edges. The fabric is applied to the ends and pressed with a heated iron. When the glue melts, the surface should be smoothed with a soft cloth.

Table drawing

Cut out parts

Paste over surface edges

Assembling the bedside table

Making a manicure table with your own hands begins with assembling the stand. Holes are made in the sidewalls for a large shelf, which will subsequently be attached to dowels pre-treated with glue. The work is carried out in stages:

- The rods are screwed in 1.5 cm from the holes made for the large shelf.

- There are 4 holes in the back plate. In the blank for a 45x29 cm shelf, holes are drilled 1 cm from the edge, in accordance with the diagram.

- The fasteners are impregnated with wood glue, installed into the surface of the shelf, and fixed to the base.

- The second strip is lubricated with glue and connected to a large shelf using eccentrics.

- Holes are made 20 mm from the edge, and the door hinges are secured with self-tapping screws. The counter strips are fixed in the same way, at a distance of no more than 5 cm from the edge.

The bedside table is turned over, holes are created in the upper and lower walls, the diameter of which is 5 mm. They serve to install dowels, which ensure the strength of the manicure table. All fasteners are pre-lubricated with glue.

The cabinet is assembled using hexagons. Before creating any holes, you should consult the drawings.

Make holes and insert rods into the sides of a large shelf

Drill holes according to the diagram

Connect shelves

Secure door hinges

Leg attachment

To make your own manicure tables reliable and durable, you need to complement them with a suitable leg. Finished products are sold in construction stores. Thick metal options are optimal, preferably rubberized ones. If necessary, you can make the base yourself using small wooden blocks.

To install the legs, you need to drill holes 25 cm from the edge. An eccentric and a dowel are placed inside - this type of fastener is relevant for mobile manicure tables. Stationary equipment involves the use of furniture corners. You should first check whether the drilled holes match the sides of the cabinet.

Install furniture legs

Attach the leg to the tabletop

Tabletop installation

The drawer side is attached to the small side panel using confirmations. The working surface is fixed using corners. In this case, the length of the edge of the cutout for the large side bar should coincide with the drawer. The easiest way to do the work is on an inverted structure.

Step-by-step restoration of an old table, ideas for original decoration

The required height is marked on the large side bar, the table top is applied, and screwed with fasteners. Holders for shelves are placed in the holes made. The final stage will be the installation of a part with parameters 45x28 cm.

After completing the assembly of the structure, finishing is carried out. Wood models are sanded, varnished, and painted with paints. A DIY manicure table made from laminated chipboard has an attractive appearance, so there is no need to use additional decor.

Table to order

If there is no financial opportunity to purchase a high-quality table, some craftsmen decide to make it themselves, because buying material and accessories will generally cost less than the finished product. In addition, by ordering such a table from a private craftsman at an inexpensive price, it is possible to obtain the most complete set of required functions.

The cost of a table, both ready-made and ordered, ranges from 6 to 30 thousand rubles, depending on the configuration and quality of the raw materials. If, when starting your own business, all available funds have been spent, and it is not possible to buy a table of the required quality, then this piece of furniture can be rented.

Homemade manicure table - drawings, dimensions, assembly

The table can be assembled with your own hands; in terms of the composition of its elements, it is no different from any other - for example, a written one. Its design usually involves fastening shelves from above to the tabletop, and drawers from below. The author can choose the design according to his own taste.

The easiest way is to make a table with a built-in bedside table supported on one leg. You will first need a drawing and calculation of the amount required to purchase accessories and materials. The latter can be MDF or laminated chipboard, that is, a sheet of wood. You will also need a PVC edge, table legs, handles for drawers, as well as hinges and fastening materials, such as self-tapping screws.

It is also worth stocking up on shelf holders, PVA glue, as tools you should take care of a jigsaw, scissors, screwdrivers, a ruler, etc.

The chipboard sheet is cut out according to the selected drawing, then everything is assembled into parts and fastened together. A detailed video explaining the entire procedure for making and assembling a manicure table yourself is easy to find on the Internet these days. The result will be an elegant table of individual design, which will delight the owner with an excellent level of comfort and the presence of all the necessary functionality.

Tools and materials

You can make a manicure table with your own hands from almost any available materials. Usually this is natural wood, plywood, OSB. Chipboard, laminated chipboard, and MDF boards are ideal for these purposes.

Taking into account the features, parameters, and necessary stability of the structure, the best material for manufacturing is chipboard sheets with a thickness of 16 mm. Natural wood is perfect for a manicure table, but the material is expensive, and its processing requires experience and special equipment.

Tips for making a computer desk with your own hands, stages of work

It is better to make the body of the manicure table from chipboard, the tabletop and facades from laminated chipboard. Working with such materials usually does not cause serious difficulties even for beginners; it is enough to have minimal skills. Tools you will need:

- Jigsaw. Used for sawing material in a vertical plane.

- Screwdriver. Allows you to quickly connect elements of a manicure table.

- Sander. Serves to remove roughness and surface defects. If the tool is not available, you can replace it with sandpaper, but in this case the polishing process will take much longer.

- Drill. Indispensable when drilling holes for fastening parts of a manicure table.

- Construction adhesive. Used for additional fixation of fasteners.

- Nails and screws. With their help, structural elements are attached.

- Ruler. Better metal, 500–1000 mm long.

Manicure tables made independently are almost in no way inferior to similar products produced in furniture factories. If sawing, grinding of parts, as well as assembly of the structure are carried out carefully, and the dimensions correspond to individual preferences, the model will turn out to be even more durable and practical compared to factory products.